Carbon Steel F56 Flanges Manufacture, Supplier and Exporter in Mumbai, India

Yaman Steel, located in Mumbai, India, has built a solid reputation as a reliable manufacturer and supplier of top-notch Carbon Steel F56 Flanges. Renowned for their precision, durability, and consistent performance, Yaman Steel guarantees that each flange adheres to strict international standards. The company caters to various industries, including oil and gas, petrochemical, construction, and power generation, offering products that blend strength, reliability, and the ability to withstand extreme conditions. Their Carbon Steel F56 Flanges are specifically designed to endure high pressure, temperature changes, and mechanical stress, making them perfect for critical piping systems, industrial plants, and structural applications that require long-lasting performance.

Carbon Steel F56 Flanges Price List in Mumbai, Carbon Steel F56 Flange Supplier in Mumbai, Carbon Steel F56 Flanges Exporter in Mumbai, Carbon Steel F56 Flange Supplier in Mumbai, Carbon Steel F56 Flanges Exporter in Mumbai, Carbon Steel F56 Flanges Size Chart, CS F56 Flanges Price in India, Carbon Steel F56 Flanges ThickneCS F56, Carbon Steel F56 Flange Supplier in Mumbai, CS F56 Flanges Stockist in Mumbai, Carbon Steel F56 Flanges Exporter in India

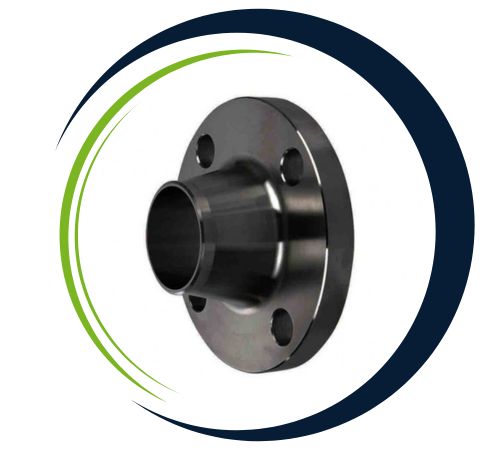

Carbon Steel F56 Flanges

These flanges are primarily made from carbon steel, featuring a carbon content of about 0.56%, along with carefully controlled levels of manganese, phosphorus, and sulfur to boost their mechanical properties. They showcase impressive tensile and yield strength, outstanding toughness, and good ductility. Thanks to their uniform composition, they deliver consistent performance even under stress, pressure, and varying environmental conditions. With excellent weldability and sturdy construction, Carbon Steel F56 Flanges resist deformation, corrosion, and wear, making them ideal for heavy-duty industrial and engineering applications.

Carbon Steel F56 Flange Exporter in India, Carbon Steel F56 Flanges Price List in Mumbai, Carbon Steel F56 Flanges Supplier in Mumbai, Carbon Steel F56 Flanges Exporter in Mumbai, Carbon Steel F56 Flanges Exporter in Mumbai, Carbon Steel F56 Flanges in India, CS F56 Flange Size Chart, Carbon Steel F56 Flanges Price in India, Carbon Steel F56 Flanges Weight Chart, CS F56 Flanges Supplier in Mumbai, Carbon Steel F56 Flanges Stockist in Mumbai

Carbon Steel F56 Flanges Specification

| Material Specification Of : | ASTM A694 F56 Flanges |

|---|---|

| Pressure Rating | Class 150 To Class 2500 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

| Common Types Of Flanges: | Slip On (SORF), Weld Neck (WNRF), Blind (BLRF), Lap Joint (Loose), Threaded (NPT), Socket-Weld (SWRF) |

| Special Types Of Flanges : | Nipoflange, Elboflange, Latroflange, Swivel Flange, Expanding Flange, Reducing Flange, Weldoflange |

| Marking Standard | Name of Manufacturer Schedule Type of Flange Facing Nominal Pipe Size Pressure Class ASME B16 Designation |

| Bolt Type | high strength bolts medium strength bolts low strength bolts |

| Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

| Size Chart | Normal Pipe Size 1/2 to NPS 24″ |

| Thickness | Normal Pipe Size ≤ 18 |

| Bore Diameter | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| European Standard Flanges | JIS B2220 Flanges (5k to 30k) and KS1503 flanges |

| Russian-Standard Flanges | GOST 12820 / 12821-80, DIN, UNI, EN 1092-1 |

| South African Standard Flanges | SANSflanges And SABS flanges |

| Surface Finish | smooth, concentric serrated, stock |

| Gaskets Types | Full Face Gasket Flat Ring Gasket Metallic Ring Gakset |

| Advantages Of Pipe Flange | Used to Connect Pipe System Easy Repair Pipe System Assembled Without Welding |

Carbon Steel F56 Flanges Chemical Composition

| Carbon [C] | ≤0.30 |

| Manganese [Mn] | ≤1.60 |

| Phosphorus [P] | ≤0.025 |

| Sulfur [S] | ≤0.025 |

| Silicon [Si] | 0.15-0.35 |

Carbon Steel F56 Flanges Mechanical Properties

| Element | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| ASTM A694 F56 Flanges | 415 | 315 | 20 % |

Types of Carbon Steel F56 Flanges

If You Are Looking To Buy High Quality

Carbon Steel F56 Flanges Supplier in Mumbai, Carbon Steel F56 Flanges Weight Chart, Carbon Steel F56 Flange Exporter in Mumbai, CS F56 Flanges Manufacturer in Mumbai, Carbon Steel F56 Flanges Price List in Mumbai, Carbon Steel F56 Flange Sizes in mm, CS F56 Flanges Distributor in Mumbai, Carbon Steel F56 Flanges in India, Carbon Steel F56 Flanges Distributor in India

Largest Carbon Steel F56 Flanges Manufacturer and Exporter in Mumbai, India

Yaman Steel is the largest manufacturer and exporter of Pipe, Fittings, Flanges in Mumbai, India, known for delivering high-quality products to clients across the globe. With state-of-the-art manufacturing facilities and a team of skilled professionals, the company ensures flanges with superior strength, durability, and reliability that meet international standards. Yaman Steel offers a wide range of sizes, grades, and specifications, catering to industries such as oil and gas, petrochemical, power, and water treatment. For inquiries and orders, contact us at sales@pipefittingsflanges.com.

Uses of Carbon Steel F56 Flanges

You’ll find Carbon Steel F56 Flanges commonly used in oil and gas pipelines, petrochemical plants, power generation facilities, water treatment projects, and large-scale construction industries. They play a crucial role in piping systems, ensuring secure and leak-proof connections between pipes, valves, and equipment. Perfect for high-pressure and high-temperature applications, these flanges promise durability, reliability, and a long service life. Their excellent weldability and mechanical toughness make installation a breeze while ensuring they perform well under extreme conditions, making them a go-to choice for engineers.

- Oil and gas industry

- Pulp and paper industry

- Power plants

- Energy industries

- Modern architecture

- Fluid piping

- Dairy and food processing

- Heat exchanger

- Textile machinery

- Water waste projects

- Synthetic fiber

- Exhaust gas and Exhaust air

- Construction

- Automotive industry

- Transporting materials

Our Products

Worldwide Shipping